Lithium Extraction Optimisation Plant LEOP.

Vulcan LEOP – The plant.

In November 2023, Vulcan opened the Lithium Extraction Optimization Plant (LEOP) in Landau, Germany. The lithium extraction optimization plant represents an investment of more than 40 million euros for Vulcan. The LEOP is used for optimization, operational training and product qualification tests.

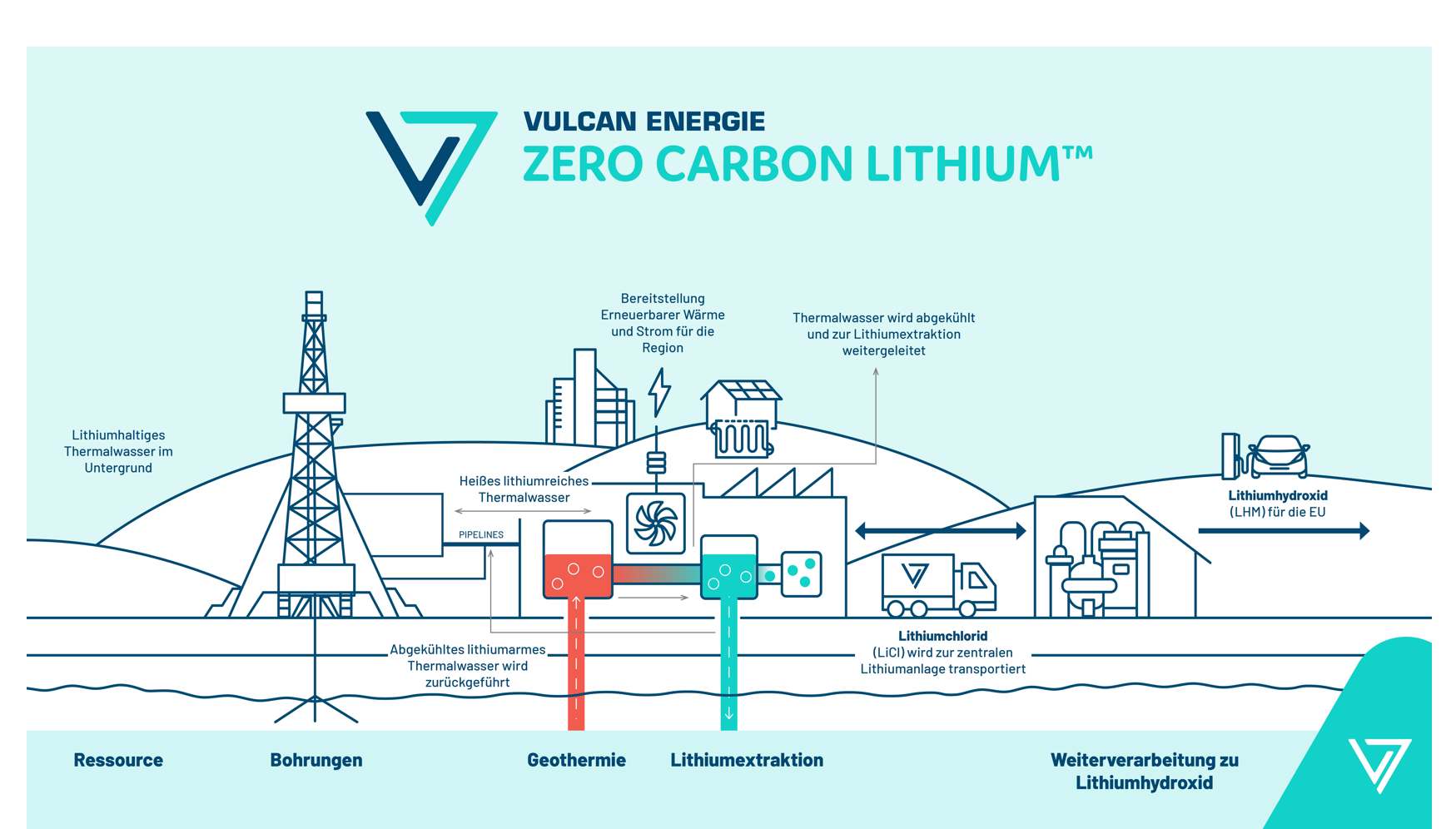

To extract lithium from thermal water, we use the Direct Lithium Extraction adsorption process, which has been commercially proven in the lithium industry since the 1990s. Compared to conventional extraction processes, this has advantages such as lower operating costs, lower water consumption and a smaller CO2 footprint.

Vulcan's Domestic lithium.

In April 2024, Vulcan started producing the first lithium chloride (LiCl) from the Lithium Extraction Optimization Plant (LEOP). This is the first LiCl to be produced for Europe from a local source along an entirely locally sourced value chain in Europe.

We transport the lithium chloride extracted in the LEOP to the downstream lithium processing plant, the Central Lithium Electrolysis Optimization Plant (CLEOP). There, the lithium chloride is converted into lithium hydroxide monohydrate (LHM), the raw material for the battery industry.

Vulcan's smarter and more sustainable Lithium extraction process.

Lithium production and renewable energy through several Vulcan locations.

Vulcan generates renewable energy from deep geothermal energy and ZERO CARBON LITHIUM™ in several plants at various locations. Processes and process improvements are also continuously tested in the Vulcan laboratory. Our geothermal power plant in Insheim already produces renewable energy for the neighbouring communities and is home to two of our test plants.